Understanding plastic manufacturing is crucial for producing high-quality, cost-effective products that meet the requirements of consumers and industries. This article provides an overview of the plastic manufacturing process and guidelines for selecting the optimal material for your application.

Understanding plastic manufacturing is crucial for producing high-quality, cost-effective products that meet the requirements of consumers and industries. This article provides an overview of the plastic manufacturing process and guidelines for selecting the optimal material for your application.

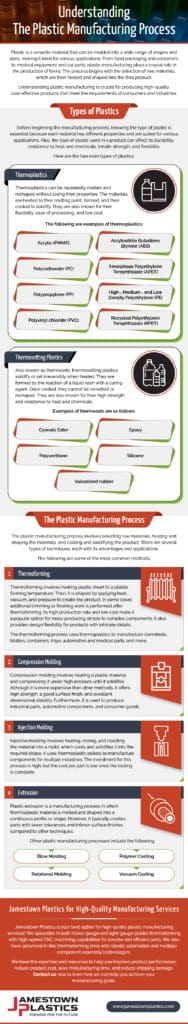

Types of Plastics

Before beginning the manufacturing process, knowing the type of plastic is essential because each material has different properties and are suited for various applications. Also, the type of plastic used in a product can affect its durability, resistance to heat and chemicals, tensile strength, and flexibility.

Here are the two main types of plastics:

Thermoplastics

Thermoplastics can be repeatedly melted and reshaped without losing their properties. The materials are heated to their melting point, formed, and then cooled to solidify. They are also known for their flexibility, ease of processing, and low cost.

The following are examples of thermoplastics:

• Acrylic (PMMA)

• Acrylonitrile butadiene styrene (ABS)

• Amorphous Polyethylene Terephthalate (APET)

• Polycarbonate (PC)

• High-, Medium-, and Low Density Polyethylene (PE)

• Polypropylene (PP)

• Polyvinyl chloride (PVC)

• Recycled Polyethylene Terephthalate (RPET)Thermosetting Plastics

Also known as thermosets, thermosetting plastics solidify or set irreversibly when heated. They are formed by the reaction of a liquid resin with a curing agent. Once cooled, they cannot be remelted or reshaped. They are also known for their high strength and resistance to heat and chemicals.

Examples of thermosets are as follows:

• Cyanate ester

• Epoxy

• Polyurethane

• Silicone

• Vulcanized rubberThe Plastic Manufacturing Process

The plastic manufacturing process involves selecting raw materials, heating and shaping the materials, and cooling and solidifying the product. There are several types of techniques, each with its advantages and applications.

The following are some of the most common methods:

Thermoforming

Thermoforming involves heating plastic sheet to a pliable forming temperature. Then, it is shaped by applying heat, vacuum, and pressure to create the product. In some cases additional trimming or finishing work is performed after thermoforming. Its high production rate and low cost make it a popular option for mass-producing simple to complex components. It also provides design flexibility for products with intricate details.

The thermoforming process uses thermoplastics to manufacture clamshells, blisters, containers, trays, automotive and medical parts, and more.

Compression Molding

Compression molding involves heating a plastic material and compressing it under high pressure until it solidifies. Although it is more expensive than other methods, it offers high strength, a good surface finish, and excellent dimensional stability. Furthermore, it is used to produce industrial parts, automotive components, and consumer goods.

Injection Molding

Injection molding involves heating, mixing, and injecting the material into a mold, which cools and solidifies it into the required shape. It uses thermoplastic pellets to manufacture components for multiple industries. The investment for this process is high, but the cost per part is low once the tooling is complete.

Extrusion

Plastic extrusion is a manufacturing process in which thermoplastic material is melted and shaped into a continuous profile or shape. However, it typically creates parts with lower tolerances and inferior surface finishes compared to other techniques.

Other plastic manufacturing processes include the following:

• Blow molding

• Polymer casting

• Rotational molding

• Vacuum castingJamestown Plastics for High-Quality Manufacturing Services

Jamestown Plastics is your best option for high-quality plastic manufacturing services! We specialize in both heavy-gauge and light-gauge plastic thermoforming with high-speed CNC machining capabilities for precise and efficient parts. We also have advanced in-line thermoforming lines with robotic automation and multiple component assembly technologies.

We have the expertise and resources to help you improve product performance, reduce product cost, save manufacturing time, and reduce shipping damage. Contact us now to learn how we can help you achieve your manufacturing goals.