Thermoforming 101: The Ultimate Guide

What Are the Benefits of Using Plastics in Manufacturing?

Plastic is an extremely versatile and adaptable material, making it applicable to virtually every industry. In addition, it offers the following advantages that make it superior to other materials in the manufacturing sector:

Providing Customers with Cost-Effective Thermoforming Solutions

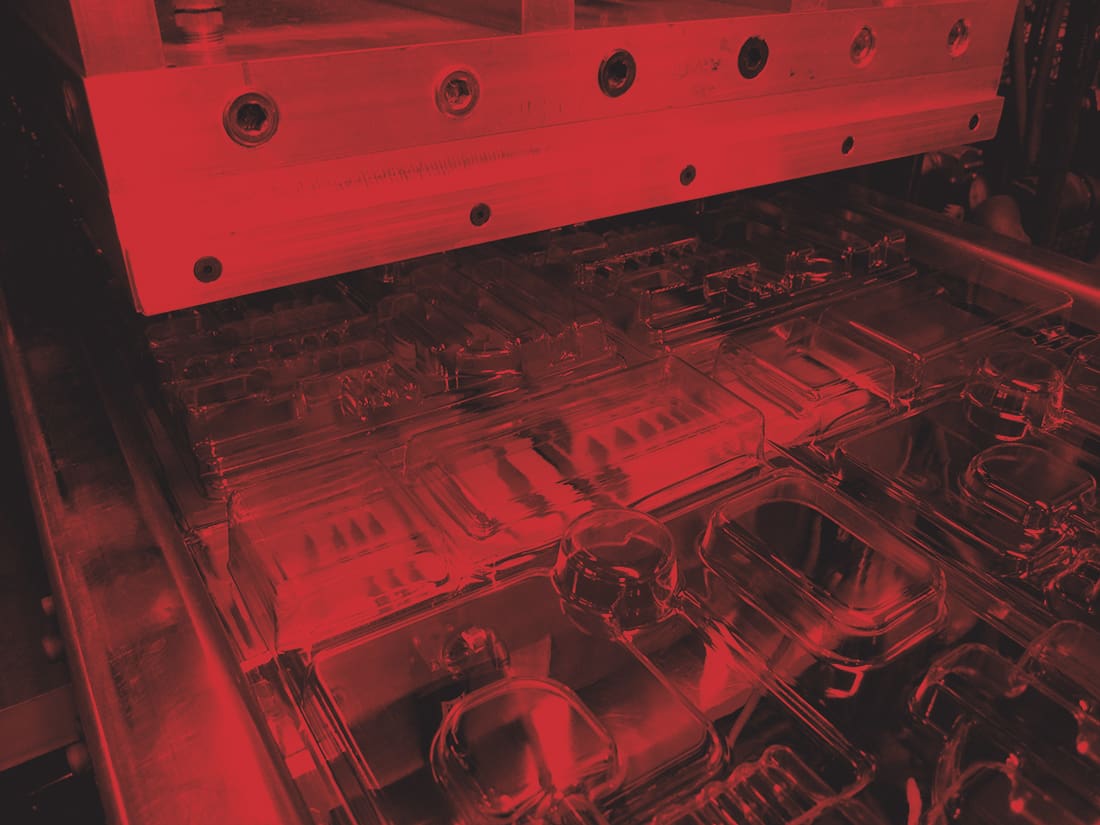

Thermoforming is a cost-effective technique for producing intricate shapes from plastic. It transforms thermoplastics by heating/vacuuming/applying pressure to the plastic sheet material. It utilizes a variety of machines to produce plastic products, including high-speed in-line thermoforming lines with robotic automation, light-gauge roll-fed machines, and larger sheet-fed machines for heavy gauge thermoforming.

This plastic manufacturing process enables the production of parts with lower production costs and may not require additional machining or tooling. As a result, it is a preferred technique for manufacturing a wide variety of components, including clamshell packaging, blister packaging, automotive appliques, dunnage trays, returnable tote tray systems, covers, and bumpers.

What are the Advantages of Custom Plastic Thermoforming?

Thermoforming provides various advantages that make it a suitable plastic part manufacturing method. The benefits of plastic thermoforming include:

- Allows for adding details and creating custom designs

- Economical

- Excellent for manufacturing both small and large parts

- Has a short prototyping and development cycle

- Requires lower tooling investment compared to other processes

Because of the mentioned advantages, thermoforming is frequently used across multiple industries, including electronics, agriculture, automotive, consumer products, packaging, medical, and marine.

What Are Some of the Most Common Thermoforming Techniques?

There are three distinct thermoforming techniques: vacuum forming, pressure forming, and twin sheet forming.

How to Properly Select a Plastic Thermoforming Manufacturer

Each plastic thermoforming manufacturer provides a distinct set of capabilities; therefore, it is necessary to find one specializing in a specific project’s essential aspects. Consider the following factors when selecting a thermoforming partner:

- Material availability and expertise

- Equipment and manufacturing capabilities

- Design and engineering team competence

- Production capacity and additional services

- Standards and certifications

- Pricing

What Are Other Effective Plastic Manufacturing Processes?

Aside from thermoforming, several other processes are frequently used in manufacturing plastic products. Here are some examples:

We Don’t Let Down Our Customers

Jamestown Plastics is committed to customer satisfaction by adhering to ISO 9001- and 13485-certified quality standards for testing, inspection, traceability, process control, and documentation. Our customers also value this dedication, as we consistently perform well on key success metrics, such as on-time delivery, product acceptance, and overall client satisfaction.

We offer plastic thermoforming services to numerous industries, including the automotive, consumer goods, electronics, medical, and general industrial sectors. Further, our team also provides value-added services to expedite the market delivery of the products.

Providing Top-Tier Plastic Manufacturing Services Through Authenticity & Passion

At Jamestown Plastics, we guarantee that the methods and expertise we provide customers are of the highest quality and standard. We perform our design and tooling work in-house, giving us complete control over every aspect of a project and allowing us to reduce lead times as needed.

Our experts can help you in producing plastic products of the highest quality! Contact us for more information about our products and services.