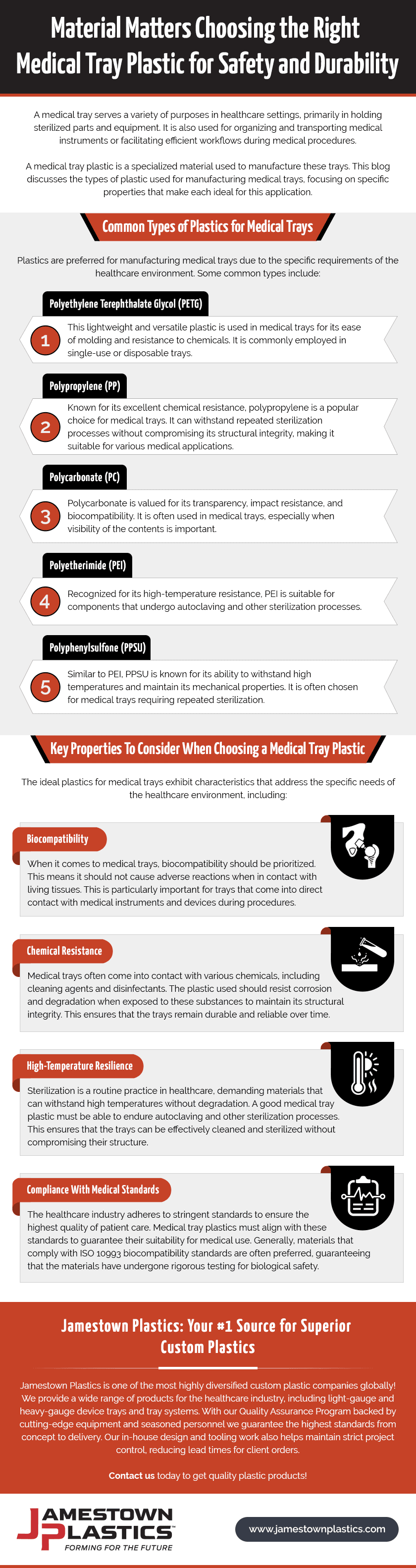

A medical tray plastic is a specialized material used to manufacture these trays. This blog discusses the types of plastic used for manufacturing medical trays, focusing on specific properties that make each ideal for this application.

Common Types of Plastics for Medical Trays

Plastics are preferred for manufacturing medical trays due to the specific requirements of the healthcare environment. Some common types include:

- Polyethylene Terephthalate Glycol (PETG): This lightweight and versatile plastic is used in medical trays for its ease of molding and resistance to chemicals. It is commonly employed in single-use or disposable trays.

- Polypropylene (PP): Known for its excellent chemical resistance, polypropylene is a popular choice for medical trays. It can withstand repeated sterilization processes without compromising its structural integrity, making it suitable for various medical applications.

- Polycarbonate (PC): Polycarbonate is valued for its transparency, impact resistance, and biocompatibility. It is often used in medical trays, especially when visibility of the contents is important.

- Polyetherimide (PEI): Recognized for its high-temperature resistance, PEI is suitable for components that undergo autoclaving and other sterilization processes.

- Polyphenylsulfone (PPSU): Similar to PEI, PPSU is known for its ability to withstand high temperatures and maintain its mechanical properties. It is often chosen for medical trays requiring repeated sterilization.

Key Properties To Consider When Choosing a Medical Tray Plastic

The ideal plastics for medical trays exhibit characteristics that address the specific needs of the healthcare environment, including:

Biocompatibility

When it comes to medical trays, biocompatibility should be prioritized. This means it should not cause adverse reactions when in contact with living tissues. This is particularly important for trays that come into direct contact with medical instruments and devices during procedures.

Chemical Resistance

Medical trays often come into contact with various chemicals, including cleaning agents and disinfectants. The plastic used should resist corrosion and degradation when exposed to these substances to maintain its structural integrity. This ensures that the trays remain durable and reliable over time.

High-Temperature Resilience

Sterilization is a routine practice in healthcare, demanding materials that can withstand high temperatures without degradation. A good medical tray plastic must be able to endure autoclaving and other sterilization processes. This ensures that the trays can be effectively cleaned and sterilized without compromising their structure.

Compliance With Medical Standards

The healthcare industry adheres to stringent standards to ensure the highest quality of patient care. Medical tray plastics must align with these standards to guarantee their suitability for medical use. Generally, materials that comply with ISO 10993 biocompatibility standards are often preferred, guaranteeing that the materials have undergone rigorous testing for biological safety.

Jamestown Plastics: Your #1 Source for Superior Custom Plastics

Jamestown Plastics is one of the most highly diversified custom plastic companies globally! We provide a wide range of products for the healthcare industry, including light-gauge and heavy-gauge device trays and tray systems. With our Quality Assurance Program backed by cutting-edge equipment and seasoned personnel we guarantee the highest standards from concept to delivery. Our in-house design and tooling work also helps maintain strict project control, reducing lead times for client orders.

Contact us today to get quality plastic products!