The Go-To Custom Thermoformer

Industry-Leading Custom Thermoforming

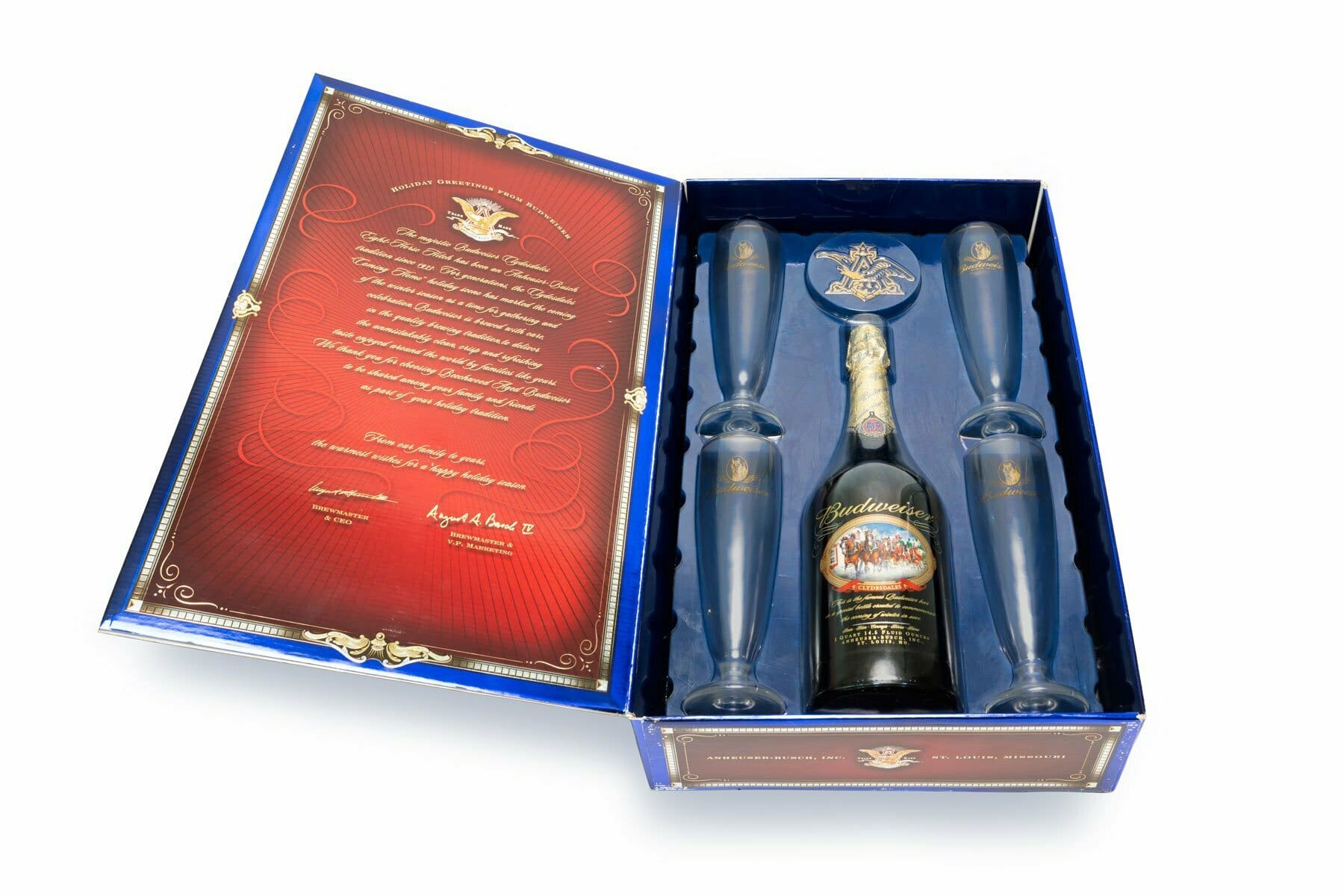

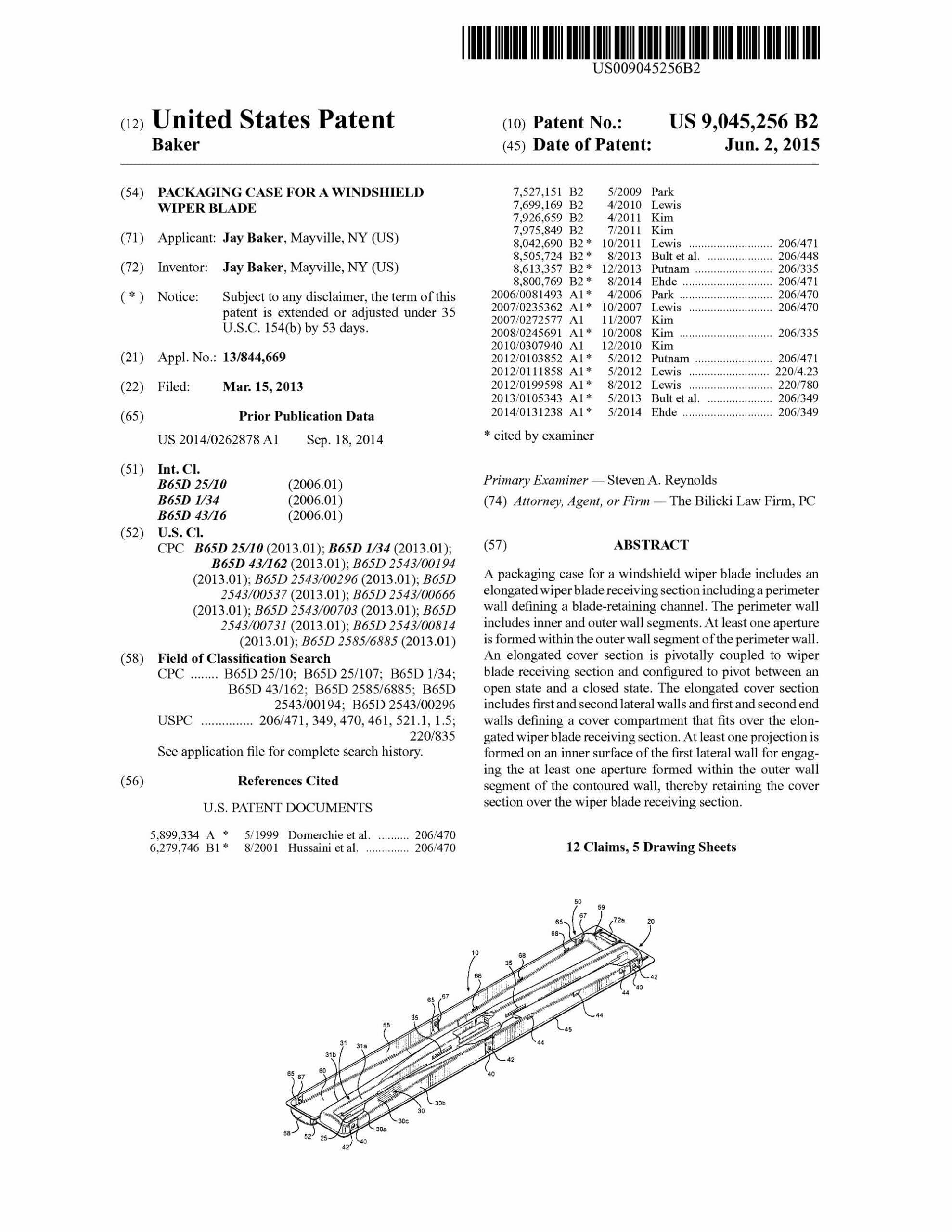

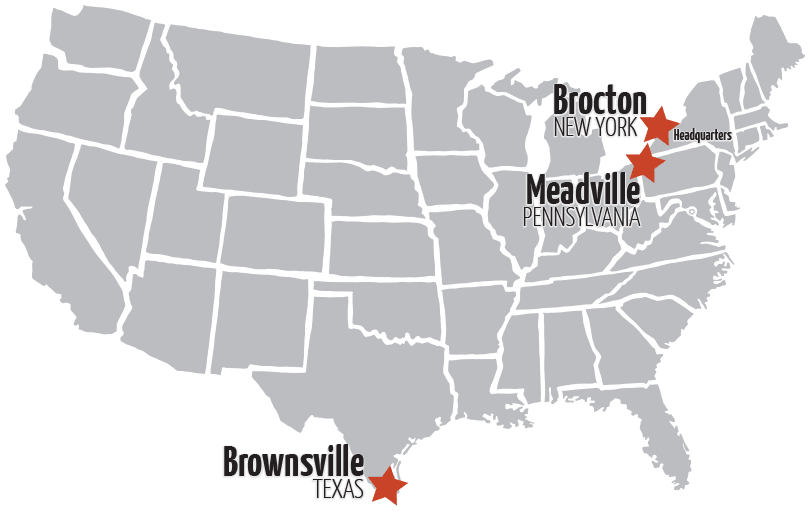

For more than 67 years, Jamestown Plastics has built a reputation as one of the most highly diversified custom plastic companies in the world. Our operations prioritize quality in every step, from design to production, resulting in products that meet the highest standards. Managing all design and tooling in-house allows us to maintain complete control over projects, achieve exceptional precision, and reduce lead times. In addition, the Jamestown Plastics teams holds an unprecedented number of US utility patents in the thermoforming world.

Looking Ahead

Jamestown Plastics remains steadfast in its mission to innovate, adapt, and deliver high-quality custom plastic solutions. As we continue to grow, our focus remains on improving efficiency, reducing costs, and driving success for our customers across industries.